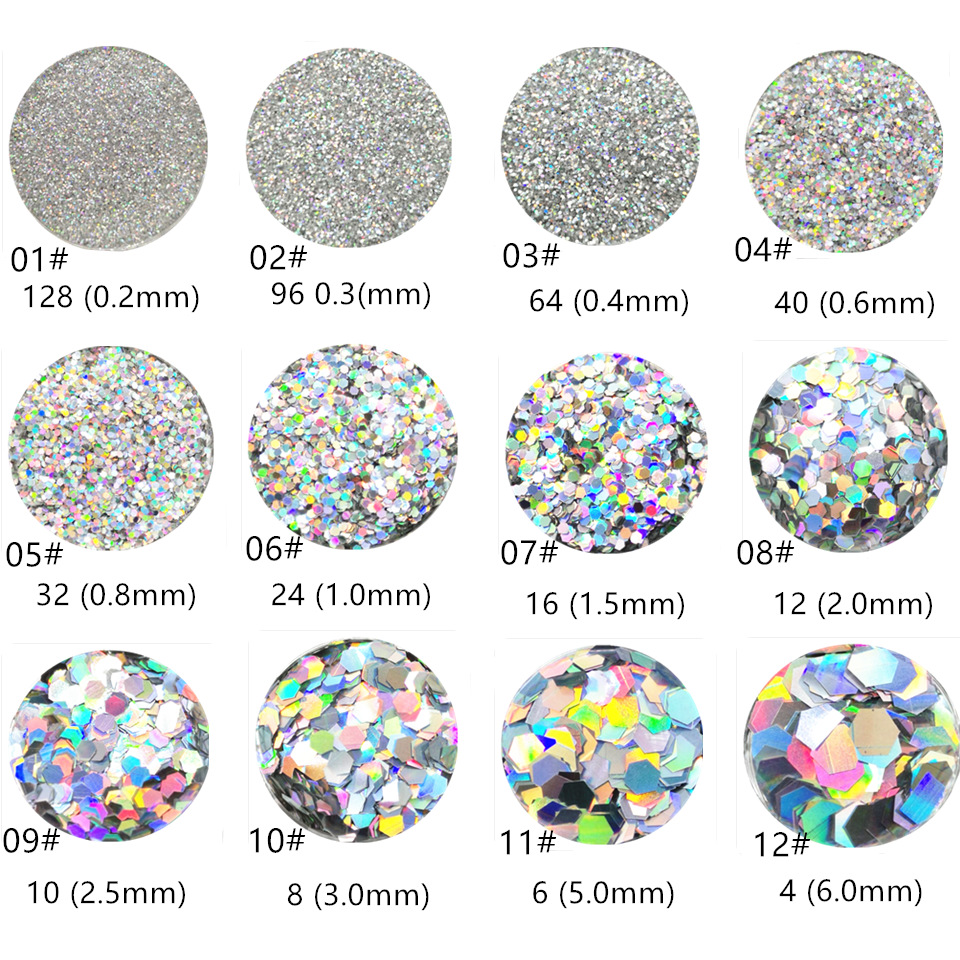

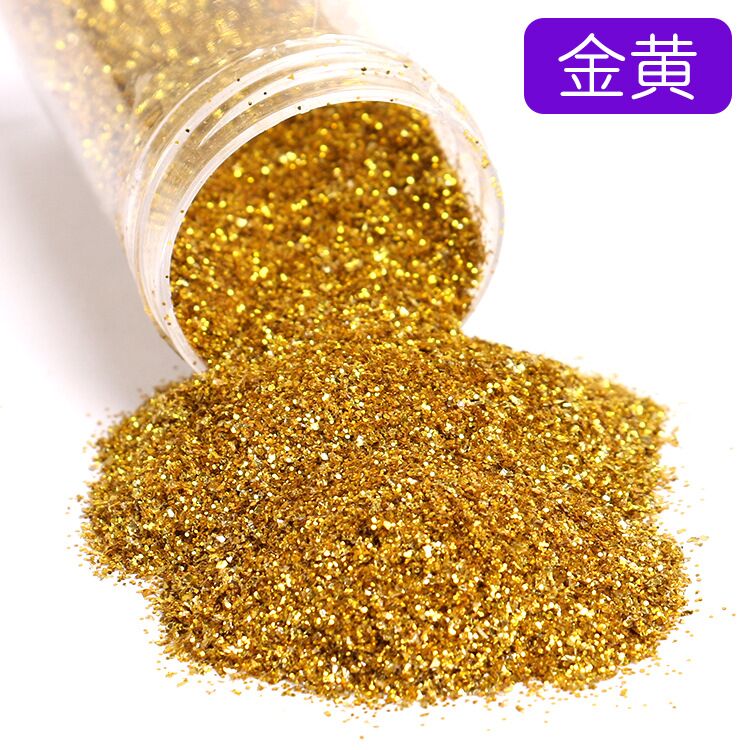

【Main glitter shapes】

Quadrangle: 0.1mm、0.3mm、0.4mm、0.5mm、0.6mm、0.8mm、1.0mm、3.0mm

hexagonal : 1/500(0.05mm)、1/360(0.07mm)、1/256(0.1mm)、1/170(0.15mm)、1/128(0.2mm)、1/96(0.3mm)、1/64(0.4mm) 1/40(0.5mm)、1/32(0.6mm)、1/24(0.8mm)、1/20(1.3mm)、 1/12(2.0mm) 、1/10(2.5mm)、1/8(3.0mm)

Strip: 0.3x1.5mm 、0.3x3mm、0.3x4.7mm

【Product Standards】

There are many types, colors and specifications of glitter powder, and high-quality glitter powder is reflected in the following indicators:

1. High brightness: distinguished from the surface brightness, the high-quality glitter powder has high flash, high brightness, and obvious mirror effect.

2, the shape is unified: high-quality glitter powder, the shape of the glitter powder under the microscope, the shape is uniform, showing a standard hexagon. The shape does not appear to be different in size and powder.

3. Resistant to strong acids and bases: High-quality glitter powder, long-term immersion in strong acid and strong alkali liquids to maintain bright colors.

4. High temperature resistance: It can be cooked in a way that the gold onion powder will not be faded or partially discolored after being cooked at high temperature. This method is mostly used to identify glitter powder for glitter gel and nail polish.

【Production Process】

The entire production process of ordinary glitter powder is divided into five parts, which are vacuum plating, high-temperature coating and printing, slitting, cutting powder, sieve powder removal, and other processes. The core process that determines product quality is the production process of high-temperature coating and printing. This process will determine the brightness, high-temperature resistance and solvent resistance of the glitter powder.

【Application】

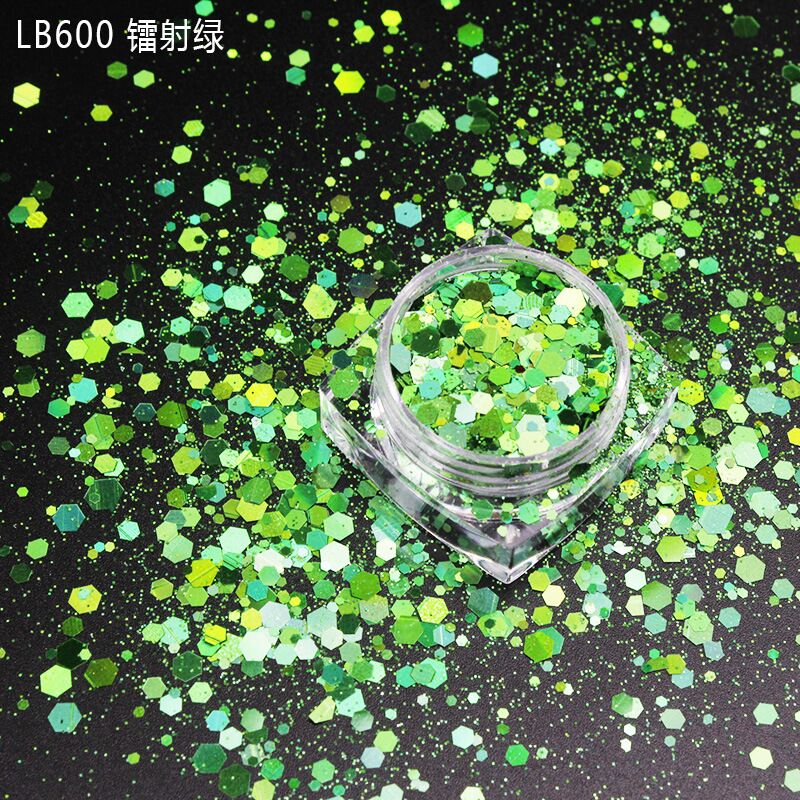

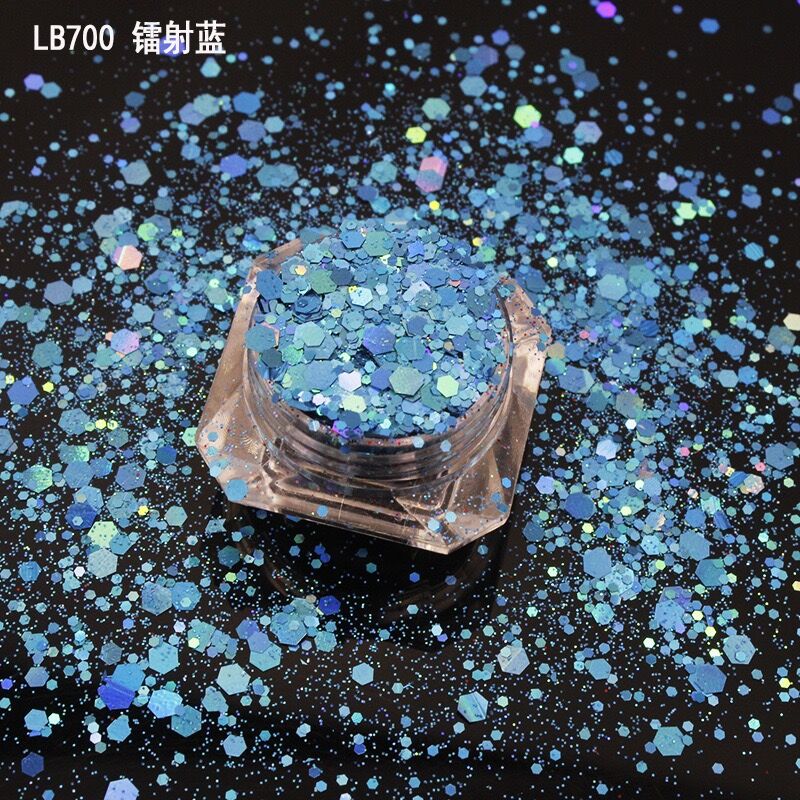

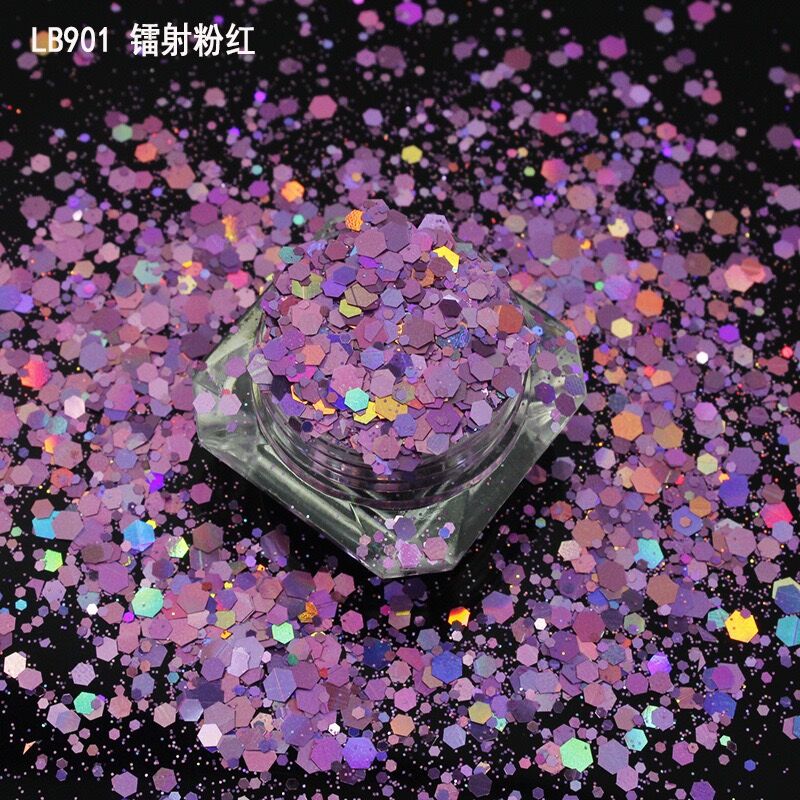

Glitter powder is a kind of surface treatment material with unique effect. It is widely used in Christmas crafts, candle crafts, cosmetics, screen printing industry (cloth, leather, footwear --- shoes materials, new year series) , Decorative materials (craft glass art, polycrystalline glass; crystal picture glass crystal ball), paint decoration, furniture painting, packaging, Christmas gifts, toy pens and other fields, which are characterized by enhancing the visual effect of the product, making the decorative part uneven Level, more three-dimensional.

And its highly glittering characteristics make the decoration bright and dazzling. There are also cosmetics, as well as eye shadows in the field of cosmetics, as well as nail polish and various nail products. Glitter powder has a wide range of applications in the food packaging industry due to the bright effect of plastic film plus coating. With the continuous development of technology, the application of glitter powder in the whole field will become more and more extensive.